Dedicated services and support offered by those who are experts in their fields

Knowledge and state-of-the-art services

Our highly specialized technical team is able to develop and propose assertive solutions for each operating reality, always working together with our customers while giving special attention to all needs and particularities, even the more specific ones.

And due to this dedication to details, we are considered a reference in service by our customers every year. *

*Annual Mercurio satisfaction surveys

Services

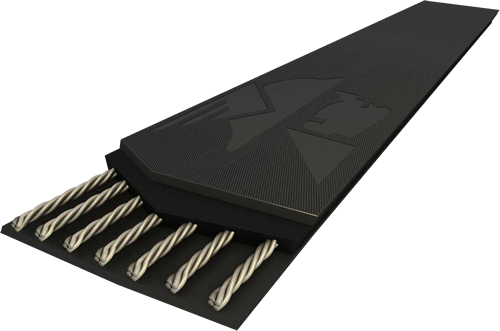

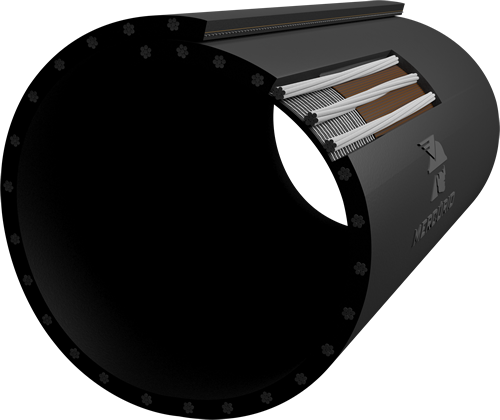

SCANNER

Applied to steel cord conveyor belts, the scanner performs predictive maintenance, assessing cord and splice integrity.

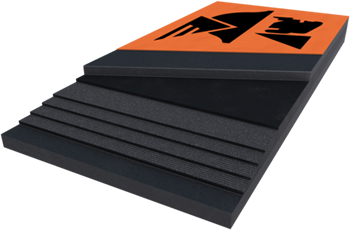

ULTRASOUND

By measuring the thickness of the rubber covers, the ultrasound device makes it possible to assess the conveyor belt’s performance.

THERMAL ANALYSIS

Detects and diagnoses high temperatures in the materials transported, allowing them to be adapted to the application.

LISTING AND MAPPING

Making a complete list of the technical and dimensional data of the equipment for adjusting and standardizing the conveyor belts.

PROJECT ANALYSIS

We evaluated new or existing designs to indicate the most appropriate belt specifications for the best cost x benefit x useful life.

APPLICATION ENGINEERING

We technically analyze the conveyor and monitor the belt’s performance, which allows us to identify the problem and indicate the best solution with lifetime gains.

INVENTORY OPTIMIZATION

After analyzing and standardizing items, we optimize your inventory, thus contributing to reducing expenses.

TRAINING

We offer training courses that help improve your knowledge of conveyor belt inspection, applications, and splicing.

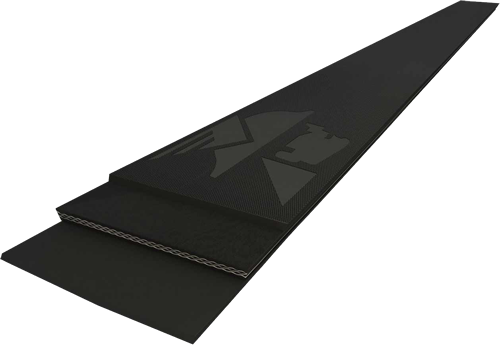

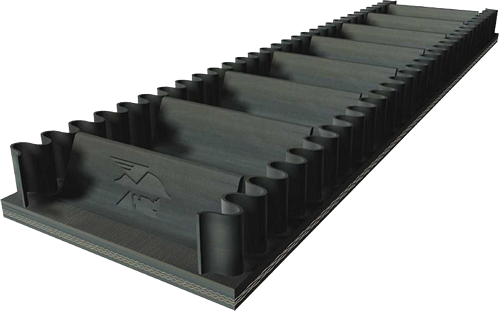

CONVEYOR BELT SPECIFICATION

We evaluate the particularities of each application and specify the most adequate conveyor belt considering the best cost x benefit x service life analysis.