Offering customized, efficient, and tailored products to solve the most critical problems of our customers is one of the challenges that drives the Mercurio team in its pursuit of a constant evolution. Check out this success case and see how we do this with excellence!

Responsible for the annual production of nearly 30 million tons of iron ore, one of Brazil’s major iron ore companies, located at 100 km from Belo Horizonte, in the city of São Gonçalo do Rio Abaixo, has three ore crushing plants. One of them, the fines plant, accounts for 15% to 20% of all the ore processed at the complex.

In the first stage of crushing, the stones have a granulometry of up to 300 mm (boulders), which need to be fragmented to reach the desired granulometry. For this purpose, the ore is taken to a jaw crusher, which carries out the first step of fragmentation. This piece of equipment is crucial for the operation, because the rest of the line is prepared to work with lower granulometry.

RECURRING ISSUE

The mining company was facing problems in this area, which happened when the lamellar stones passed directly through the maximum opening of the jaw crusher. When this happens, some of the boulders hit the conveyor belt hard. The cargo concentration on the contact area was ripping the belt. To make matters worse, some of the stones got stuck in this position. With the drive continuously moving the conveyor belt, the rip would spread uncontrollably.

Since the affected conveyor belt is only 30 meters long, in some cases there was no time to stop the operation before the conveyor belt was completely lost. And don’t think this was a rare thing to happen. “There were times when we had this problem up to three times in one month,” the engineer in charge recalled.

This means that the operation had to be shut down, leading to production losses, maintenance costs and the risk of accidents involving workers. “Crushing plants are sequential. When a conveyor belt stops working, the entire process stops,” he pointed out.

TEAMWORK

With over a decade’s experience in this operation, the maintenance team was aware of the severity of the application of a replacement conveyor belt. “A traditional conveyor belt would not solve our problem,” he explained. They didn’t exactly need a product that would never rip, but rather one that could prevent the damage from spreading. It was also vital that it could undergo cold splicing.

Considering the peculiarity of this case, the client contacted its suppliers, but only Mercurio accepted the challenge. “Mercurio’s engineering team came to the plant to identify the problems and characteristics of the operation,” told the engineering in charge. In a fully client-oriented process, the development of this solution involved Maintenance Engineering, the client’s Conveyor Belt Supervision Team, and Mercurio.

“We joined forces to develop something different, because I’m aware of the technical capacity we have, as well as Mercurio,” stated the engineer.

CUSTOM SOLUTION

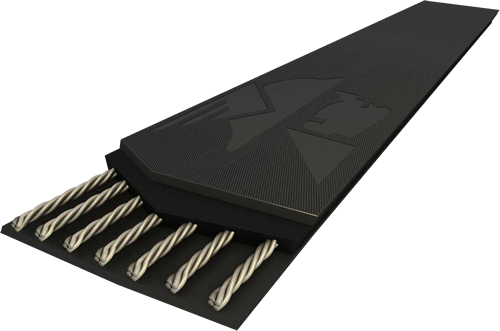

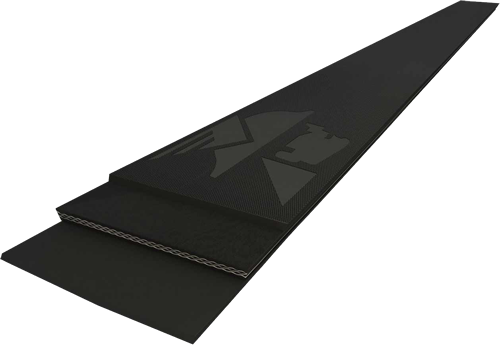

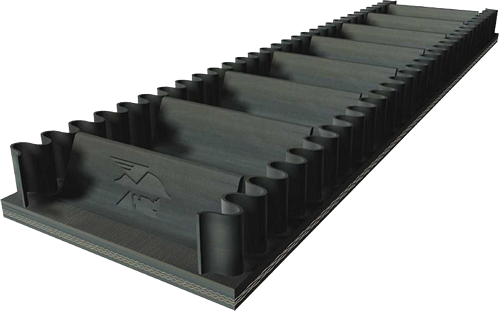

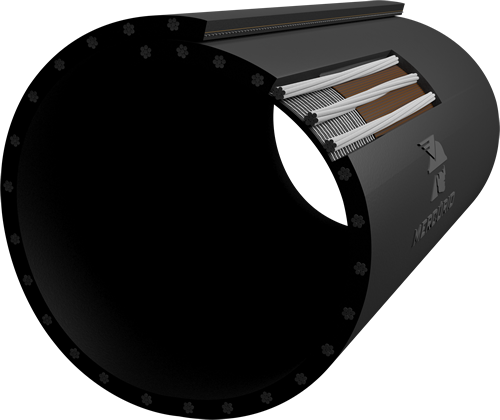

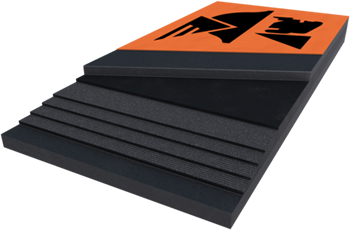

On the first try, in addition to using the MercoRip cover, which is more resilient and resistant to impact and ripping, a steel mesh (Rip Proof) was added to the top cover. The mesh aims to make the cover more resistant to movement if a boulder happens to pierce it. A sensor alerts to overload on the conveyor belt and disables the drive, preventing the rip from spreading.

“In practice, when the conveyor belt was hit by a lamellar stone 30 days after installation, it only stopped working after 17 meters,” recalled Alexandre Lacerda, an engineer at Mercurio. “The damage was considerable, and the conveyor belt had to be fully replaced,” he told. In addition, “the client needed more resistance and durability of at least one year,” he said about the time they accepted the challenge.

After the problem was identified and a solution was developed, the second test began, once again compromised by ripping. This time it was on the edge because the conveyor belt was wider than the Rip Proof. “We started over and further improved the conveyor belt,” said Lacerda. This time, in addition to the steel mesh covering the entire width, they added an aramid canvas to work as a breaker. This increased the product’s resistance to ripping and, if the conveyor belt did end up ripping, Rip Proof would reduce the extension of the damage. “We made a very robust conveyor belt, appropriate for this type of application,” celebrated the client.

SURPRISING RESULT

The conveyor belt was installed in January 2017 and was extremely successful, even with the crusher working at maximum opening and allowing more boulders to pass through. The equipment worked for 13 consecutive months, until February 2018. “It didn’t rip, but it worked so much that the superficial cover just wore down,” pondered the engineer in charge.

Because of intense client-oriented engineering work, developed in partnership with the client, the result was disseminated. “We replicated the concept in other conveyor belts and mines,” said the maintenance manager, who presented the case in internal seminars promoted by the company. Its success is so evident that the 40% to 50% higher cost, compared to the conventional solution, is absorbed by the plant’s higher reliability. “People on the field are surprised by its durability. We found a concept that works,” celebrated the client. Lacerda believes this is the most resistant conveyor belt currently offered by Mercurio, and therefore the most cost-efficient. “It pays for itself when compared to the number of conveyor belts that would have to be acquired to avoid shutdowns,” he explained.